We're about as far north as we can get in Singapore, and as far from reasonable public transport.

Arriving at the workspace of Roger&Sons on the fifth floor of Woodlands Industrial Xchange, we immediately drop any illusions that this is your regular clean glass-doored, air-conditioned office — it's noisy, dusty and cluttered with planks and piles of wood stacked against the walls, from the floor and also spilling over an unused unit next door.

Photo by Jeanette Tan

Photo by Jeanette Tan

It is here, after squeezing between a collection of stools and bar-top tables and past a couple of young men working at various tools we decided it would be better not to go anywhere near, that we steer into a small rectangular area with a wooden door and false-wall partitions.

Photo by Jeanette Tan

Photo by Jeanette Tan

And that's where we eventually find 30-year-old Morgan Yeo, almost completely obscured by two large desk monitors and an assortment of items piled high on his table and the surrounding chairs, in the middle of a phone conversation, assuring a client in a mix of Mandarin and Hokkien that he will personally oversee the timely delivery of a batch of furniture.

As soon as he gets off the line, though, he immediately apologises to us for the clutter both here and outside — they're working toward an expansion to a new space on King George's Avenue, and that'll be happening as soon as next month.

Despite the hive of activity that's going on outside, and the multiple calls he would end up skipping during our conversation, Yeo is pleasantly dedicated and passionate, switching easily between educating us about trees, wood grain and wood drying and talking numbers, financials and business strategy.

And we have to remind ourselves repeatedly — with some admiration too, we must admit — that this is a young, ambitious and big-picture-thinking Singaporean mainstream university graduate.

Where he could have gone into the corporate world to wet his feet before returning to help (and that, in fact, was what he did initially plan to do), he is in start-up mode in what is otherwise a very traditional industry.

Yeo is at the helm of Roger&Sons, a boutique carpentry firm he and his brothers inherited from his late father.

And it was his father's untimely passing from pancreatic cancer in 2014 that accelerated this process.

But four and a half years on, what Yeo, with the help of his mom and younger brothers, has been doing with Roger&Sons, is both meaningful and promising for the revival of a niche, but necessary and unconventional industry in Singapore.

Taking over at a difficult time

When Yeo took over JR & P Industries Pte. Ltd, it had just five employees and was in debt.

It was a far cry from its peak, which saw 30-40 full-time carpenters and salesmen in its employ.

Now, under Yeo's leadership, Roger&Sons is a "close-knit family" of 20, with its scope of work extending way beyond manufacturing systems furniture — what Yeo's father Roger focused solely on.

As the oldest of three of Roger's sons, Yeo would often follow his father to work and as he grew older and studied business practices, he observed and was able to deduce the reasons behind the decline of the business but decided against attempting to intervene or change things.

"That’s the way he is and that’s the way the older generation are. It’s so hard for him to change anyway."

He also shares that it wasn't easy for him as a new, young and inexperienced leader, to gain the trust of his late father's stalwarts to stay on and continue working for him and in the company.

"So at the start when they were out for installation, I’ll be there, I’ll be learning from them, I’ll be clearing their mess for them, so when they screw something, there’s dust, I’ll sweep it up for them, help them with the small stuff, carry stuff... It took about a year, a year and a half for them to really begin to believe in what I was doing."

Humility is key, says Yeo, who says he learns new things about the trade every day.

He rattles off things that largely escape, but in an even bigger way fascinate us: humidity, the properties of various types of wood and different finishes, for instance. These, he says, are the product of learning from the carpenters he works with, and the beauty of carpentry:

"Carpentry is not just one guy who knows everything. Even the old guys who have been around for 10-20 years, somebody new might just come up with a new idea that’s better. That’s the good thing about carpentry... we problem-solve every day."

[related_story]

Making good use of locally-felled & discarded trees

But this story, to some extent, has been told before. Yeo actually opens our conversation telling us about Singaporean trees — as it turns out, there were many that were getting cut down and just, well, sitting around.

They're cut down for different reasons, shares Yeo — developmental and safety being the chief two, and also, in some cases, because they are sick.

They're supposed to be turned into mulch, that will in turn go back to the soil, but in reality, Yeo shares with a raised brow, they are kept and then disposed of.

"In theory, when a contractor gets approved to do a project leased by NParks, they are supposed to dispose of the trees. But they don’t do it, they keep it and hopefully they are able to use it eventually, to sell their trees. Because that’s how people who do disposals make money. They help you 'dispose' of it but you don’t have to know what they do after. Like the karang gunis who repurpose things."

Finding Singaporean tree lobangs

Now the trees are almost free — we say almost, because the contracting companies holding the trees are actually quite glad to be rid of them, but the cost, as with all other situations in Singapore, comes from finding space to store them.

In fact, storage costs make Singaporean trees more expensive as a source of wood than trees from Indonesia, where most of the wood Roger&Sons uses.

And in case you're wondering why Yeo doesn't just cut up the wood to size and start using it right away, it's because the trees have to first be air-dried — a process that takes up to six months.

Thankfully for Yeo, he found a lobang: tree disposal contractors who owned sawmills and their accompanying storage spaces they inherited in Sungei Kadut (an area also very far up north), willing to let go of the already-air-dried trees ("these trees have been around for ages") for "a couple hundred dollars".

Why not buy directly from NParks? Yeo did try, but learned of the difficulty of justifying giving trees to a commercial entity that plans to make money from the wood obtained.

So with that, Yeo came up with an ingenious idea: build quality, specially-designed furniture using the solid wood from these Singaporean trees, in the form of what he's going to call the Local Tree Project.

He hopes to not only build and sell special, completely-locally-sourced and made-in-Singapore wood furniture (they've already started, by the way), but also to educate the public about what happens to Singaporean trees when they get cut down.

And his supply of trees isn't going to abate anytime soon — according to a Straits Times report, some 13,000 trees have been slated to be chopped down in the next 15 years.

Photo by Jeanette Tan

Photo by Jeanette Tan

Taking a gamble on solid wood, specially-designed furniture

The Local Tree Project is something Yeo hopes to be able to eventually turn Roger&Sons sustainable, in view of an impending big change to the company's revenue model.

He shares that his staff is focused on two main types of work:

- traditional plywood and laminate furniture (what most of your cupboards, wardrobes and cabinets are made from), which also includes office systems furniture; and

- specially-designed furniture under the Local Tree Project that involves the "more intricate carpentry work", utilising solid wood.

And right now, the plywood and laminate team's work accounts for some 60 per cent of the company's revenue, effectively making it the main source of income for the company and an important means of sustaining the second team.

And the work coming from the plywood and laminate team isn't going anywhere — so necessary it continues to be that Yeo shares the two carpenters remaining from his father's time "have been working with plywood and laminate for their entire lives".

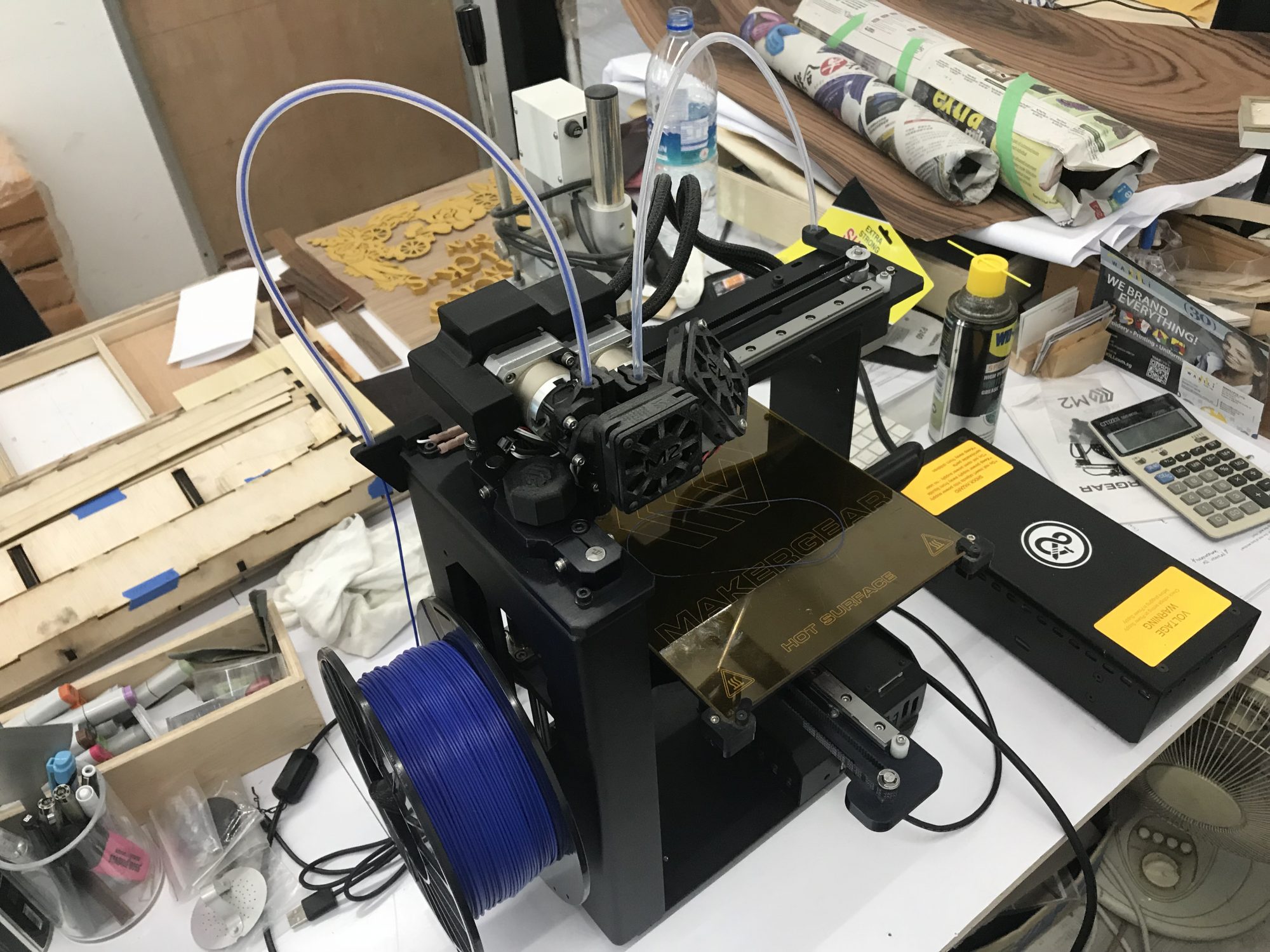

Team 2, meanwhile, is where Yeo works on innovating and introducing new techniques for furniture or accessory-making — which explains the 3D printer occupying a significant area of the table in his office we are seated at:

Photo by Jeanette Tan

Photo by Jeanette Tan

On this team are several young industrial designers working to push the boundaries of furniture design.

This block of wood made from a corroded tree, for instance, can be filled with coloured resin for a cool effect. (Photo by Jeanette Tan)

This block of wood made from a corroded tree, for instance, can be filled with coloured resin for a cool effect. (Photo by Jeanette Tan)

This new direction Yeo is taking, he explains, is a practical one:

"I think interior design, anyone can do. There are so many interior design folks in Singapore. Plus, every house looks the same in Singapore and you must buy from more or less the same place. It’s all pretty standard. So I felt that there was no point in going into that space unless you are very, very good...

But now we provide industrial services — industrial design which is a different ball game. We can do 3D printing, we can do more different unique stuff that I feel people will be willing to pay for."

Yeo acknowledges that while the profit from this team is not as substantial because of the amount of time and effort involved, as well as much higher costs from the quality of the material used (solid wood as opposed to plywood), it is growing.

And so this is his gamble — to grow the work of the Local Tree and bespoke carpentry team aggressively enough to replace the planned phasing out of their systems furniture unit.

Keeping the team lean

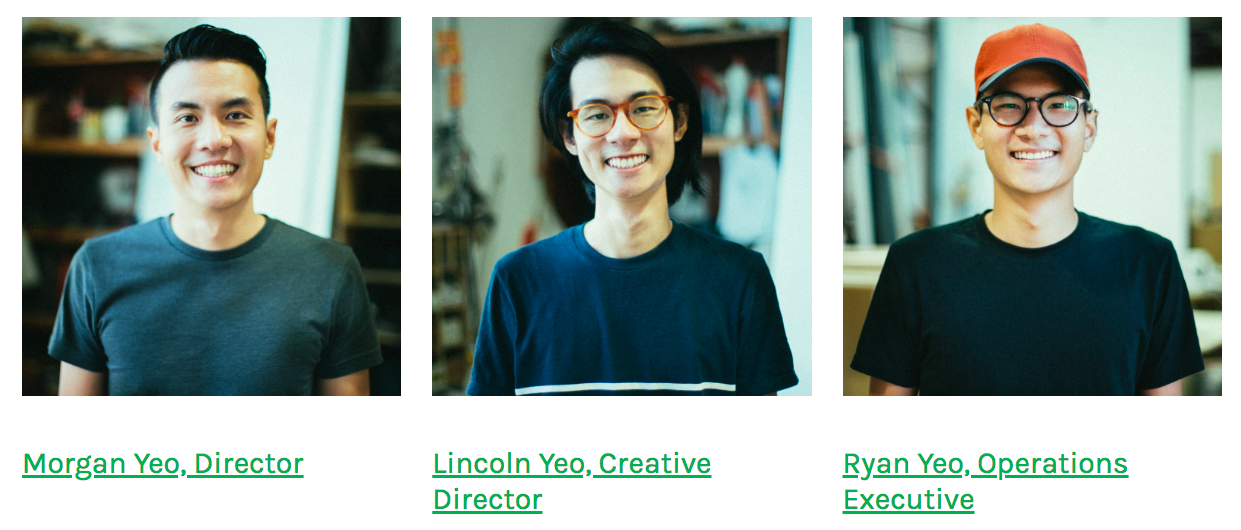

Photo via Roger&Sons website

Photo via Roger&Sons website

Contrary to notions of growth and scaling to, say, a multinational level, Yeo is clear that Roger&Sons should be maintained as a lean ship with a team committed and dedicated to his vision.

"I don’t want to overwork anyone, just keep them at a comfortable pace; we're building a brand and we are building their skills."

But if there is one thing that has not changed since his father's time, it's the manner in which the company is run — as a family:

"We care for them and if they have a problem in the middle of the night, they call me, I’ll be there. The way we run is the same but the things we are doing is different."

Yeo also feels a great sense of responsibility towards his fellow colleagues and employees, especially for some of his younger employees who will eventually get married.

"...I have to make sure they earn enough to take care of their family right?"

Interestingly, this also reveals the profile of the people who tend to seek out joining Roger&Sons — young men and occasionally women.

Photo by Jeanette Tan

Photo by Jeanette Tan

Yeo shares that each month, Roger&Sons receives applications from two to three people who want to work as carpenters.

While their range of experience varies, Yeo says they all have in common a desire to learn and explore new techniques, as well as a complete lack of interest in making plywood and laminate furniture.

"They want to do the intricate stuff, the cool stuff. I tell my guys also, there’ll be days you’ll be doing cool stuff, there’ll be days you’ll be doing not-so-cool stuff also right?

That’s the way the industry is. I cannot hire you and straight away give you a cool project because I don’t know who is going to give a project tomorrow. So it’s all about finding the right balance."

Growing out of the "family business" branding

Screenshot via Roger&Sons website

Screenshot via Roger&Sons website

There is one more thing Yeo is working toward — growing out of the "three brothers taking over the family business" image Roger&Sons has.

It is one of the things that likely got the attention of the government, which first featured Yeo in this video:

Which, in turn, netted him more recently an opportunity to put up a booth at the Singapore Day in Russia in September:

Photo credit: Lincoln Yeo

Photo credit: Lincoln Yeo

Photo credit: Lincoln Yeo

Photo credit: Lincoln Yeo

Photo Credit: Lincoln Yeo

Photo Credit: Lincoln Yeo

But while it's a good, true and meaningful narrative they've got going for them, Yeo hopes people will recognise them for the quality work they do, rather than just an inspiring trio of brothers determined to carry on an traditional family business.

"We are not known for the things we do. It’s a bit of a pity but not really, you know what I mean?

We don’t want to be forever known as the three brothers who took over the father’s business. We want to eventually be known for the work we do and for us to step up."

Yeo adds that while the name Roger&Sons will be kept, the logo will be changed "to tell people we are coming of age, that we are no longer young".

It is the first step towards building a new reputation where Roger&Sons will not be known as the three brothers who took over the father’s business but rather, as good carpenters in Singapore.

After all, the reputation of three brothers taking over the family business is nice at the start, Yeo says, "but we cannot do this forever."

There's a lot the young men have going for them — Yeo, for one, is headlong, plugged in 24/7 into thinking about the company (no time for girlfriends at the moment, sadly), and has plenty of exciting plans for their new space: carpentry classes, workshops and corporate events, even carpentry residences so his staff can learn new techniques and approaches to the furniture Roger&Sons makes.

With all this in the pipeline, Yeo's energy, passion and enthusiasm is infectious — we're excited for him and them too.

Top photo by Jeanette Tan

Content that keeps Mothership.sg going

??

Here's how you fake being artsy to impress your date/boss/future mother in law.

?

Read this and cry in a corner.

? ?

Kids teach us the darndest things. But it makes sense.

???

Earn some karma points here. Say real one.

If you like what you read, follow us on Facebook, Instagram, Twitter and Telegram to get the latest updates.