The paper parking coupon is ubiquitous in Singapore.

Many Singaporeans would have played a game of Parking Roulette before, tearing away tabs that are 10 or 15 minutes later than the current time.

But not many of us know how the parking coupon is created.

Turns out, a small-medium enterprise in Singapore is responsible for creating the moulds from which parking coupons are pressed.

Paper products moulds manufacturer

Singapore Memory Project recently published a video interview with Heng Chye Yam, the owner of Metalwood, a business that creates moulds for paper products.

Mothership.sg also spoke to Heng about the laborious process that goes behind making the coupon moulds.

The process

First, the Computer Design Department churns out a mould design using a specialised packaging design software.

For carpark coupons, this design would be the 85 tabs.

Next, the Laser-cutting Department transfers the design via a laser cutting machine onto plywood or Medium Density Fibre boards.

The laser cuts grooves into the boards for cutters to be affixed onto them.

Laser-cutting the grooves of the mould. Screenshot via YouTube.

Laser-cutting the grooves of the mould. Screenshot via YouTube.

The Knifing Department then creates specialised cutters. These are fashioned, trimmed, mounted, and assembled into the grooves that have been cut into the boards.

These flat metal strips will be fashioned into tab-shaped cutters. Via YouTube.

These flat metal strips will be fashioned into tab-shaped cutters. Via YouTube.

Cutters that are ready to be mounted into grooves on fibreboard or medium density boards. Via YouTube.

Cutters that are ready to be mounted into grooves on fibreboard or medium density boards. Via YouTube.

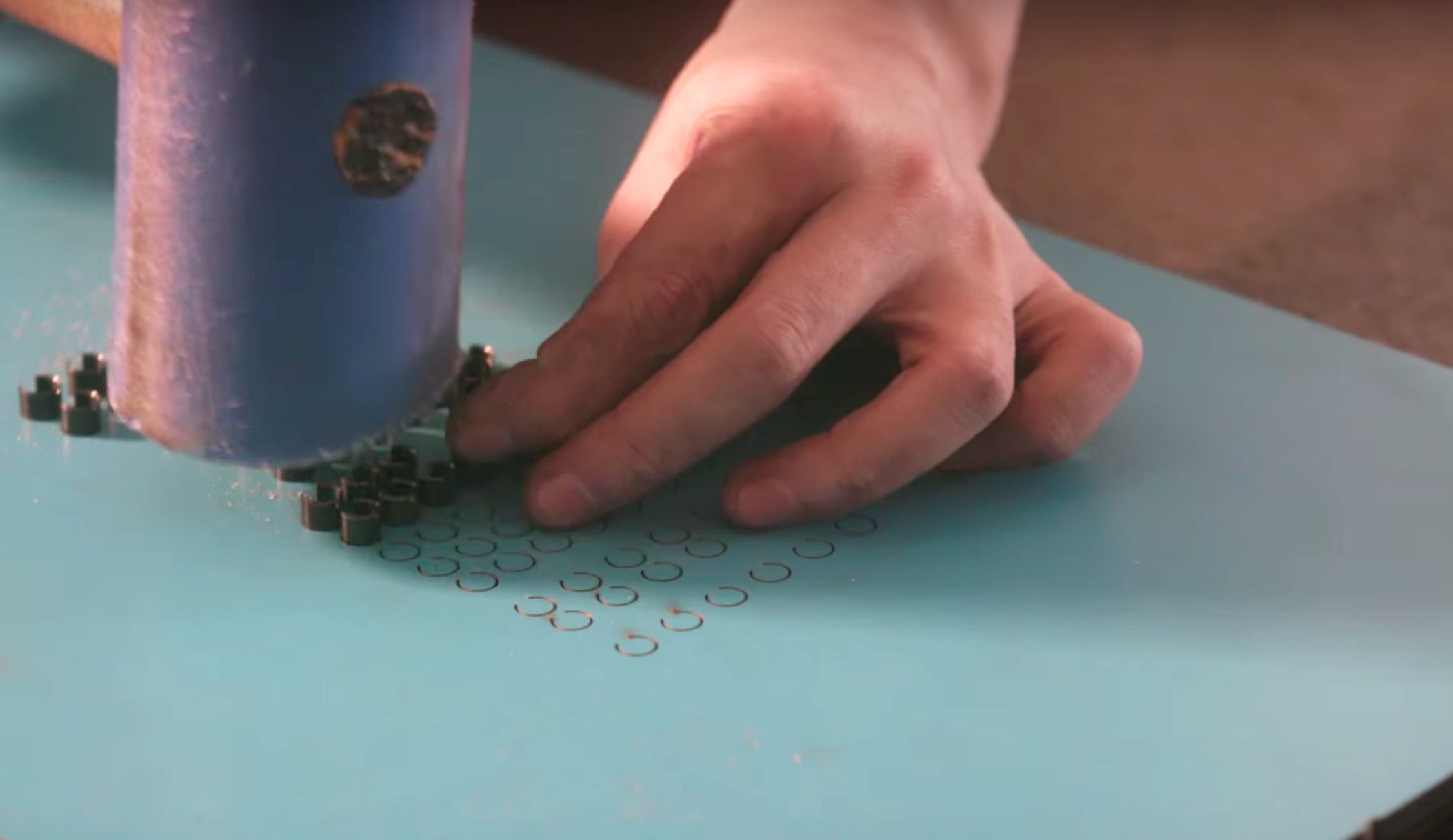

Cutters being mounted and hammered into boards. Via YouTube.

Cutters being mounted and hammered into boards. Via YouTube.

Lastly, the Quality Control Department checks the finished moulds before delivering them to their customers (mainly printing companies).

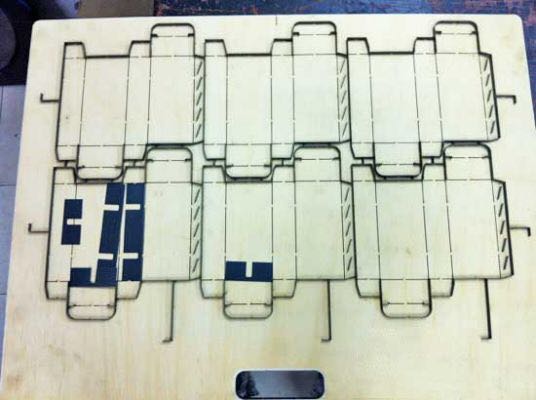

The final mould, which will be delivered to a printing company which produces the final parking coupon. Via YouTube.

The final mould, which will be delivered to a printing company which produces the final parking coupon. Via YouTube.

[related_story]

Creating moulds for various products

Aside from parking coupons, Metalwood also produces precision cut mould for paper packaging products such as cigarette cases, tissue boxes, red packets and envelopes, among other products.

A die-cut mould for cigarette packs. Image courtesy of Heng Chye Yam.

A die-cut mould for cigarette packs. Image courtesy of Heng Chye Yam.

The knifing specialist assembling the cutters onto a template board. Image courtesy of Heng Chye Yam.

The knifing specialist assembling the cutters onto a template board. Image courtesy of Heng Chye Yam.

As we move towards using digital solutions like parking apps, there will not be a future for paper parking coupon anymore.

You can watch the video interview with Heng below:

&t=103sTop image via YouTube

If you like what you read, follow us on Facebook, Instagram, Twitter and Telegram to get the latest updates.