According to Minister for Transport Khaw Boon Wan, the flooding of the North-South Line on Oct. 7 was "preventable" and "not excusable" because the engineering behind it was simple enough for a basic 101 class.

"The flooding problem is not excusable because it's so simple. We learn it as engineering students, Engineering 101. I know how to design a pit. How to calculate capacity. Those are simple stuff, the students can do. You should not have failed there."

Unfortunately, it appeared that SMRT would get a failing mark in that class, despite the numerous failsafe measures that were in place. Here's a breakdown of what went wrong.

What went wrong

Bishan MRT station, like all stations, is equipped with a small Tunnel Sump Pit that is meant to drain away water from condensation and cleaning works.

But unlike other stations, it is also equipped with a tank that can contain over 5,000m³ of water. The tank is linked to three pumps, each capable of draining water out of the tank at a rate of 85 litres (0.085m³) per second.

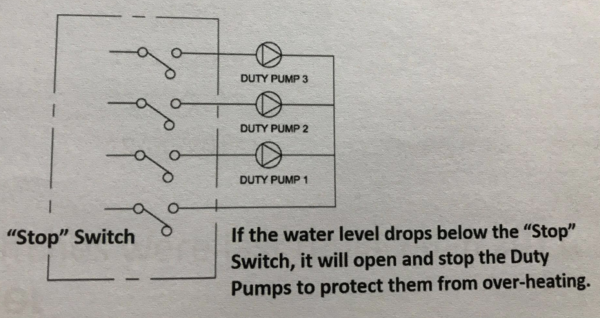

To prevent the pumps from running when the tank is empty and wearing them out, a stop switch is located at the bottom of the tank. The pumps can only activate when the stop switch is submerged in water.

1. Stop switch failed

First of all, the pumps were checked and found to be working fine. But due to the build-up of sludge and silt at the bottom of the pit, the stop switch was not working. This meant that the pumps did not activate even when water entered the pit.

Photo from LTA.

Photo from LTA.

2. Each float switch failed

Above the stop switch, three float switches are placed at ascending heights as you go up the tank. The pumps are supposed to activate when each float switch is submerged in water.

But for some reason or another, the float switches did not activate the pumps even when the switches were submerged. And so the water level in the tank rose steadily.

Screenshot from SMRT.

Screenshot from SMRT.

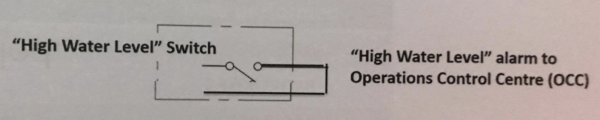

3. The high level water alert switch failed

Near the top of the tank lies the high level water alert switch. It is designed to run separately and independently from the rest of the tank's systems. This is so that even if all the other switches failed, the alert switch would serve as a final stopgap.

If the water level somehow got high enough to reach the alert switch, a signal would be sent to SMRT's Operations Control Centre, so that staff would be alerted of the impending flood.

However, the high level water alert switch with its independent system also failed, for unknown reasons.

Screenshot from SMRT.

Screenshot from SMRT.

4. The maintenance checks did not take place

A maintenance check was supposed to have taken place in Sept. 2017, which could have found that the tank was full and the switches were faulty. However, it was postponed for a month due to a lack of available slots for track access. The check was then scheduled for Oct. 12 -- unfortunately, just a few days after the flood occurred.

The last maintenance check performed in June 2017 found that the tank was empty -- but staff did not clear out the mud and sludge at the bottom of the tank after emptying out the water, as it was not part of SMRT's maintenance procedure.

When asked, SMRT CEO (Trains) Lee Ling Wee said that they would review the procedure and might amend it so that sludge is removed during maintenance.

[related_story]

5. SCDF helped out, but not part of procedure

By the time the flood was discovered, SMRT staff knew they had to drain the water before checks could be performed and service could be restored. However, they did not have the proper equipment on hand, and had to call the SCDF for help.

While Khaw expressed thanks to both SCDF and PUB for working with SMRT to solve the problem, it was clear that the team-up was done on an ad hoc basis.

As part of their review, SMRT said they planned to "tighten" their recovery plan by strengthening SOPs, cooperation and coordination with agencies such as the SCDF and PUB for the next flood.

Should not have happened

The reservoir and pumps should have been more than capable of handling the rainfall on Oct. 7. According to data from PUB, only about 640m³ of water entered the system at Bishan. This was just 13% of the tank's capacity -- had it been empty, as it was supposed to.

The fact that the tank overflowed and flooded indicated that the switches had been faulty for a long time before Oct. 7. But the fact that all these so-called failsafes failed one after another indicated that thorough changes needed to be made to SMRT's maintenance procedures.

During the press conference, LTA Deputy Chief Executive Chua Chong Kheng was asked what were the odds on so many failures occurring all at once. He declined to give a figure.

Gif from Screaming Queens.

Gif from Screaming Queens.

What's being done

SMRT has introduced a number of changes to its maintenance procedures to (hopefully) prevent the next flood.

Immediately after the Oct. 7 incident, checks were conducted on the other portal pump systems in Lavender-Kallang, Kembangan-Bedok, Redhill-Tiong Bahru and Expo-Changi Airport. All the defects found there were "rectified".

Radar sensors will be placed at all portal pump systems as redundancies for pump activation and alert warnings. Also, since the pump control panel could only be accessed if you went down to the track, SMRT is looking to relocate the control panel to a place where you don't need track access, on a case-by-case basis.

On the human side, a new integrated building and facilities maintenance division with a Chief Maintenance Officer has been created to oversee infrastructure maintenance requirements.

Also, SMRT Chairman Seah Moon Ming said that bonuses for the maintenance team at Bishan would be cut.

Hopefully this all does the trick. Or else we'll need to wear rubber boots the next time we take the train to work.

Related story:

SMRT apologises: Couldn’t someone have spoken in the past 9 days?

SMRT CEO Desmond Kuek breaks silence, addresses public

Top image by Sulaiman Daud.

If you like what you read, follow us on Facebook, Instagram, Twitter and Telegram to get the latest updates.