Follow us on Telegram for the latest updates: https://t.me/mothershipsg

Scientists in Singapore have managed to make packaging trays from chicken feathers and come up with a cheaper solution to create cultured meats using biological waste from poultry farms.

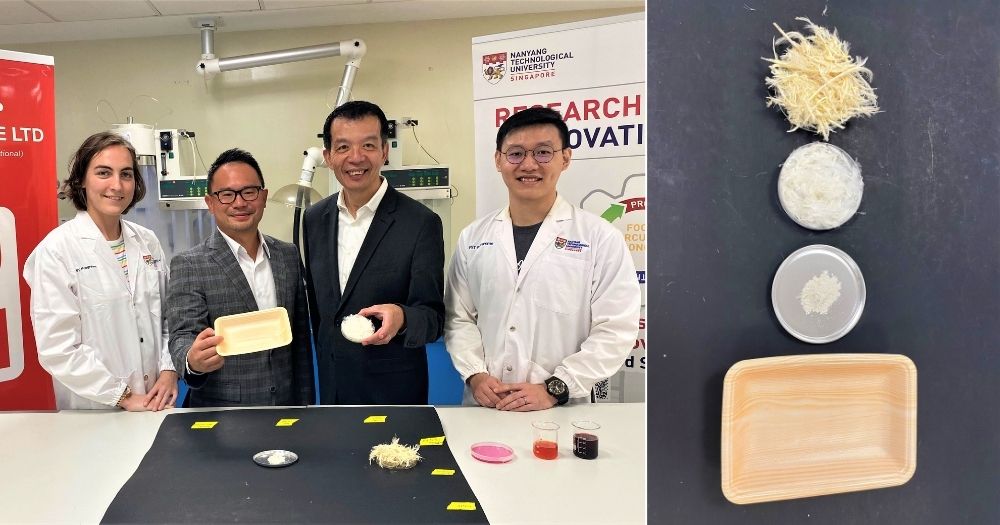

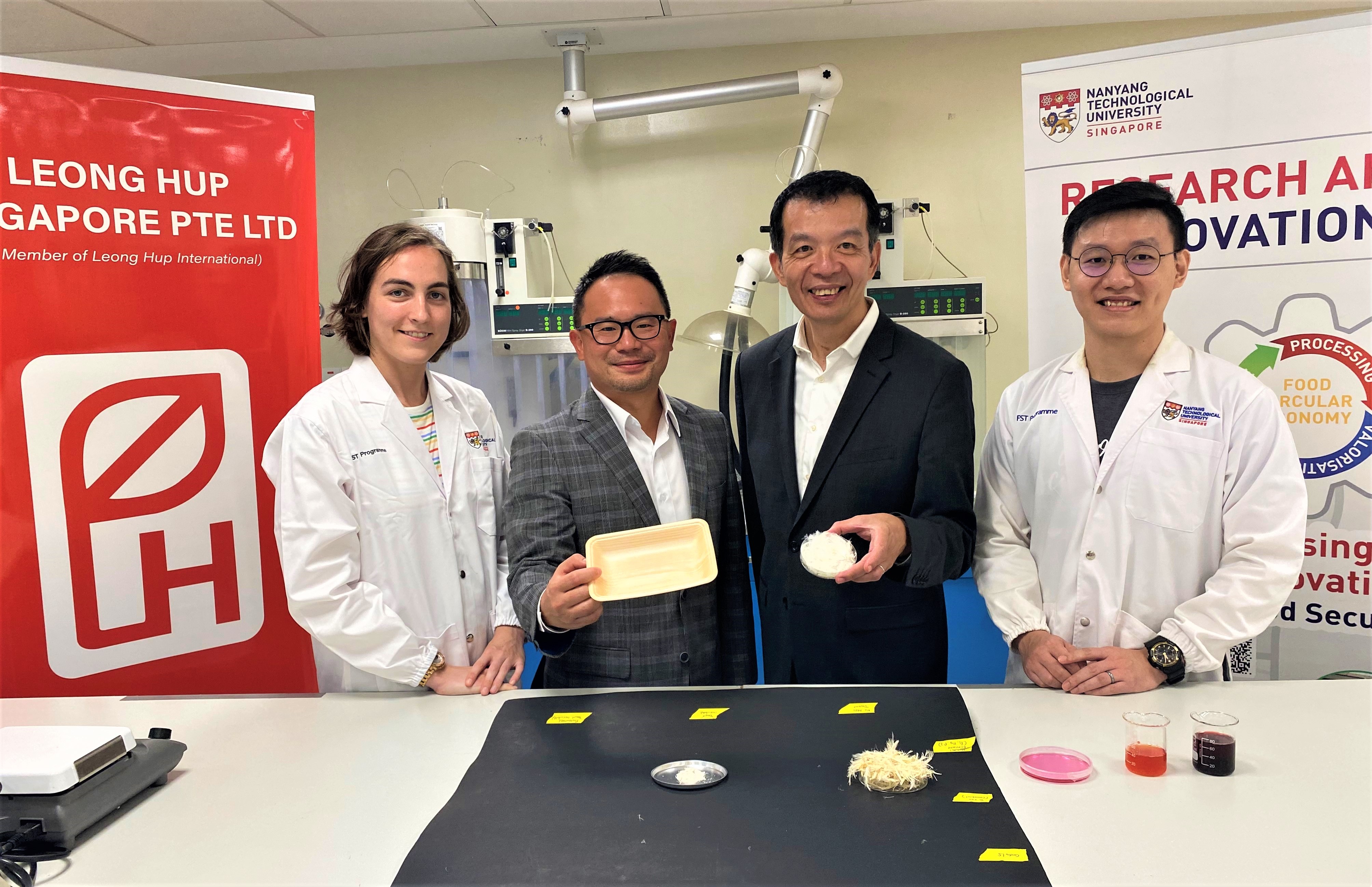

This was jointly developed by the Nanyang Technological University (NTU) and poultry producer Leong Hup Singapore.

Making egg trays from feathers

According to their press release, researchers found a novel way to use chicken feathers, a by-product from poultry processing plants.

Chicken feathers are typically treated as waste and either buried in landfills or incinerated, which contributes to greenhouse gas emissions.

The chicken feathers are washed, dried and cut, before being combined with a type of resin to make packaging trays, which can hold eggs and meat.

Chicken feathers contain keratin, a type of protein also found in human hair and nails.

Using feathers to create the packaging trays means the product is biodegradable, unlike regular plastic trays made using synthetic polymers derived from petroleum oil.

The material made from chicken feathers is also more durable and just as flexible as synthetic polymers, and can hold double the weight.

A step-by-step depiction (from top to bottom) on how chicken feathers are washed and ground into keratin powder, and the packaging materials, which they would be used to manufacture. Image by NTU Singapore.

A step-by-step depiction (from top to bottom) on how chicken feathers are washed and ground into keratin powder, and the packaging materials, which they would be used to manufacture. Image by NTU Singapore.

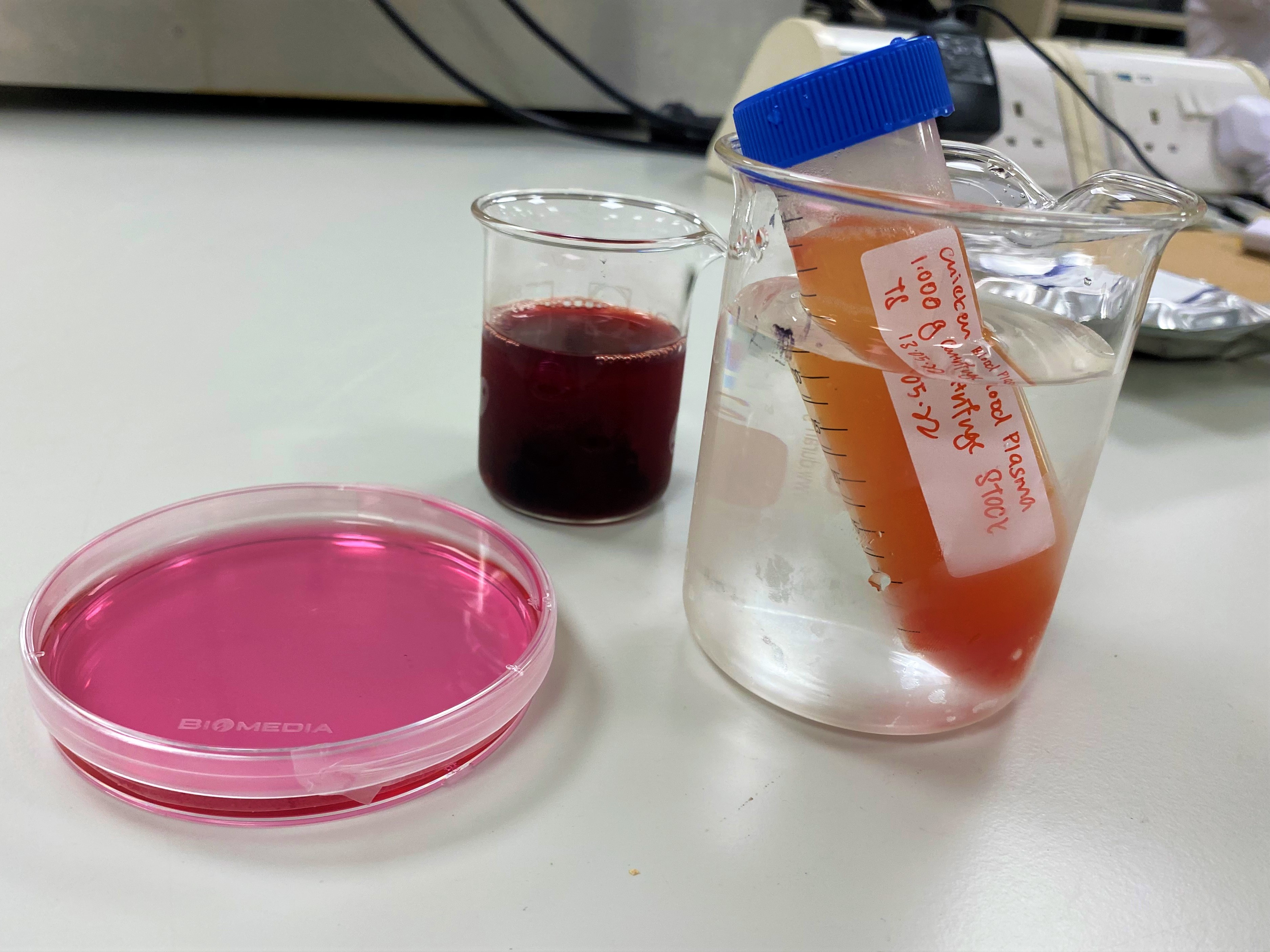

An alternative method to make growth mediums for cell-based meat

The researchers have also successfully converted biological waste from Leong Hup's poultry farming into a culture medium that can be used to grow cell-based meat.

The biological waste used includes poultry blood and bones, which are dense in organic matter and have high concentrations of growth factors and other nutrients.

The scientists were able to extract these nutrients in a cost-effective way to develop an alternative to commercial mediums for cell-based meat.

Image by NTU Singapore.

Image by NTU Singapore.

“The cultivation of lab-grown meat has the potential to reduce and even one day end the slaughter of farm animals and the impact rearing farm animals has on the environment," said William Chen, Director of NTU’s Food Science and Technology Programme and co-lead of the industry collaboration.

However, one reason that lab-grown meat is expensive is due to the high cost of the medium used to grow the meat, Chen added.

Most cell-based meat production relies on foetal bovine serum, an expensive fluid made from cow foetuses full of nutrients needed to grow animal cells.

This new growth medium made from biological waste has the potential to replace this serum as it has similar concentrations of growth factors and other nutrients, according to NTU and Leong Hup Singapore.

Image by NTU Singapore.

Image by NTU Singapore.

Scaling up production

Lau Joo Hwa, CEO of Leong Hup Singapore, said the company is currently testing these innovations in its Singapore plant.

Leong Hup operates four slaughtering plants and has the largest market share of poultry slaughtered in Singapore.

According to The Straits Times, the team plans to scale up production of their keratin trays.

Once deemed commercially viable, the poultry processing company intends to apply to the Singapore Food Agency to have its packaging certified as food-safe.

Lau also expects Leong Hup to implement the products it has developed with NTU in its overseas plants in Malaysia and Southeast Asia by 2023.

As for the newly-developed culture medium, NTU has already received interest from various alternative protein firms to commercialise the use of the product, reported ST.

Related stories

All images by NTU Singapore.

If you like what you read, follow us on Facebook, Instagram, Twitter and Telegram to get the latest updates.