Follow us on Telegram for the latest updates: https://t.me/mothershipsg

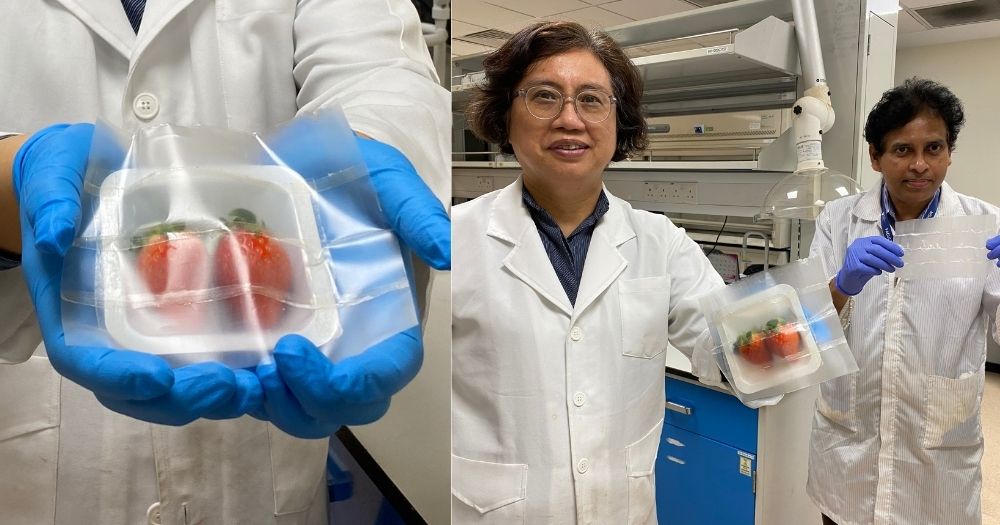

Scientists from Nanyang Technological University (NTU) and Harvard T.H. Chan School of Public Health, U.S., have jointly developed a biodegradable food packaging that can keep fruits fresh longer than the usual synthetic plastic packaging.

Biodegradable food packaging

According to NTU's news release, the biodegradable food packaging's main ingredient is zein.

Zein is produced from corn gluten meal which is a waste byproduct from corn starch or oils that are used in ethanol production.

Corn ethanol is the type of biofuel that are commonly used with gasoline to power engines in the United States.

Image screenshot from video courtesy of NTU.

Image screenshot from video courtesy of NTU.

The food packaging is made by electrospinning – an industrial method of using electric force to produce fibres – the zein, natural antimicrobial compounds with cellulose, a natural polymer starch that makes up plant cell walls, and acetic acid.

The result is a waterproof and antimicrobial material.

During lab experiments, the material releases "necessary minuscule" amounts of natural compounds that can kill common food contaminating bacteria such as E. Coli, Listeria, and fungi, when exposed to increased humidity or bacteria.

Director of NTU’s Centre of Antimicrobial Bioengineering, who is also the co-leader of the project, Mary Chan said:

"The smart release of antimicrobials only when bacteria or high humidity is present, provides protection only when needed thus minimising the use of chemicals and preserving the natural composition of foods packaged.”

Extends shelf life of food

The material's combative response to harmful microbes means that the packaging can endure several exposures, and last for months, NTU said.

The packaging can extend the shelf-life of fresh fruit by two to three days.

An experiment conducted found that strawberries wrapped in the biodegradable packaging stayed fresh for three more days, as compared to being kept in mainstream plastic boxes, and only developed mould after seven days.

Image courtesy of NTU.

Image courtesy of NTU.

This could spell a potential in reducing food waste, said Philip Demokritou, the co-lead of this project, who is an adjunct professor of environmental health at Harvard T.H. Chan School:

"One of the most efficient ways to enhance food safety and reduce spoilage and waste is to develop efficient biodegradable non-toxic food packaging materials. Stimuli triggered approaches will meet the emerging societal needs to reduce food waste and enhance food safety and quality.”

Demokritou is also the Director of Nanotechnology and Nanotoxicology Center and Co-director of NTU-Harvard Initiative on Sustainable Nanotechnology.

Other than strawberries, this biodegradable food packaging can also be used for a large variety of products, including other fruits and fresh produce, ready-to-eat foods, and raw meat.

Image screenshot from video courtesy of NTU.

Image screenshot from video courtesy of NTU.

Potential in cutting down plastic packaging waste

When scaled up, the food packaging material could serve as a sustainable alternative to synthetic plastic, the news release stated.

Synthetic plastics are derived from fossil fuels, and hence, contributes to carbon emission. Furthermore, irresponsible disposal of non-biodegradable plastic packaging has also led to pollution on land and in water.

In Singapore, 55 per cent of the 1.76 million tonnes of waste disposed by domestic sources in 2018 was plastic. One third of the waste was packaging waste.

Chan said:

"It could serve as an environmentally friendly alternative to petroleum-based polymers used in commercial food packaging, such as plastic, which have a significant negative environmental impact.”

The team of scientists are currently working on developing other technologies to develop biopolymer-based smart food package materials to enhance food safety and quality.

They hope to scale up their technology with an industrial partner to ultimately go commercial within the next few years.

Related stories

Top image courtesy of NTU

If you like what you read, follow us on Facebook, Instagram, Twitter and Telegram to get the latest updates.