Using sunflower pollen, scientists have created a sponge that is environmentally friendly and highly absorbent through a recent collaboration between Nanyang Technological University, Singapore (NTU Singapore) and Sungkyunkwan University in South Korea.

Its ability to soak up oil and other organic substances could pave the way for cleaning marine oil spills and removing contaminants from water bodies when the production is scaled up.

After more than six years, the sponge is the latest development in a series of studies exploring the potential applications of pollen. Pollen when not used for pollination has been treated as waste, according to the lead scientist of this study, Cho Nam-Joon from the NTU School of Material Science and Engineering.

“Pollen that is not used for plant pollination is often considered biological waste. Through our work, we try to find new uses for this ‘waste’ and turn it into a natural resource that is renewable, affordable, and biodegradable.

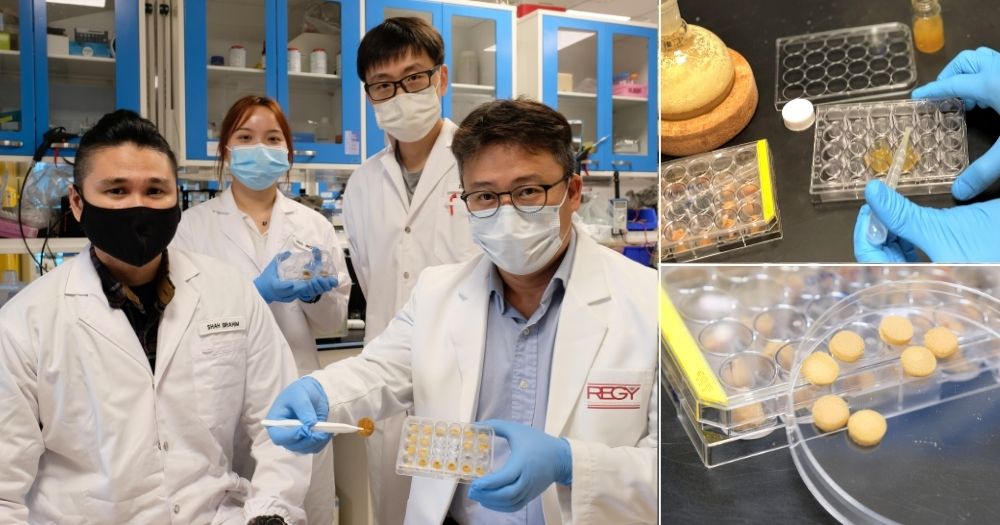

Sponge made from sunflower pollen

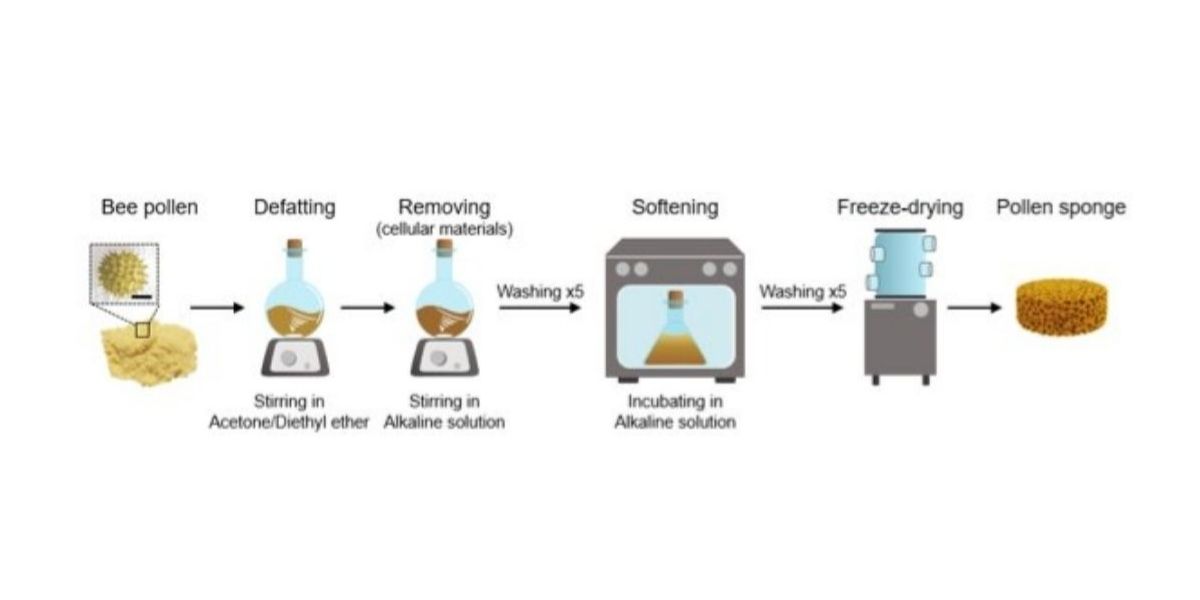

After acquiring sunflower pollen from China and Brazil, the scientists remove the pollen grain's sticky oil-based cement-like coating. The pollen is then incubated for three days in an alkaline condition.

A gel-like material emerges from the process and is freeze-dried.

Upon which, the pollen sponge is formed and the structure transforms into a 3D porous architecture.

While pollen, which was described as "the diamond of the plant kingdom", has a hard exterior, the sponge's durability is increased with brief heating at 200°C.

Pollen is abundant and so, a metric ton of sunflower pollen retails for as low as S$10. This makes pollen-made sponge a relatively low cost material.

Photo from NTU Singapore

Photo from NTU Singapore

Effective at removing oil-based liquids

Coated with stearic acid, a fatty acid commonly found in vegetable and animal fat, the sponge is hydrophobic and repels water.

This ensures the sponge absorbs oil and other contaminants effectively and will be less likely to take in water.

Oil-absorption tests, conducted with oils and organic solvents of varying densities, such as gasoline, pump oil, and n-hexane (a chemical found in crude oil), found the pollen sponge comparable to polypropylene absorbents which are currently used by companies to absorb corrosives or oil-based liquids.

Cho said: “Collectively, these results demonstrate that the pollen sponge can selectively absorb and release oil contaminants and has similar performance levels to commercial oil absorbents.”

The efficacy of the sponge was also tested by repeatedly soaking it in silicone oil and squeezing the oil out. It has shown that the sponge can be used for at least 10 times.

Believed to be able to clear up oil spills in the future

Currently, the scientists have created these biodegradable pollen-made sponges that measures up to 5 cm in diameter.

When scaled up, the scientists see a potential in these sponges being used for various purposes including to tackle oil spills.

Unlike a typical sponge, that is made of a type of refined plastic and requires significant amount of energy to produce, a pollen sponge does not introduce plastic into the oceans. Cho told the media that the team took less than eight hours to make a 5 kg pollen sponge.

The researchers hope to make bigger pollen sponges to cater to industrial demand after the trial phase.

Additionally, through collaboration with non-governmental organisations and international partners, the scientists hope to test the pollen sponges in real-life environments.

“We hope our innovative pollen materials can one day replace widely-used plastics and help to curb the global issue of plastic pollution,” said Prof Cho.

Oil spills and water contaminants

Oil spills are not uncommon, there was a global average of 1.8 oil spills from tanker related incidents that released more than 700 metric tonnes of oil into the ocean between the years of 2010 to 2019.

Detrimental to the environment, resolving oil spills is time-consuming and has limited effectiveness.

Conventional clean-up methods include dispersion, chemically breaking down the oil, burning, and absorption with costly single-use materials.

[embed]

Top image from NTU Singapore

If you like what you read, follow us on Facebook, Instagram, Twitter and Telegram to get the latest updates.