National University of Singapore (NUS) researchers have made a major breakthrough: They have found a new low cost way of producing 40 million nasopharyngeal Covid-19 testing swabs in the next few months right here in Singapore.

This new method would make use of both 3D printing and injection moulding, which is a manufacturing process.

Singapore's reliance on overseas supplies

Currently, Singapore is relying on suppliers from the United States, Italy and other parts of Europe for its swabs.

But there is a global shortage of swabs.

Countries around the world are vying to re-open their economies and are mass testing their respective populations.

Two NUS teams working on solution

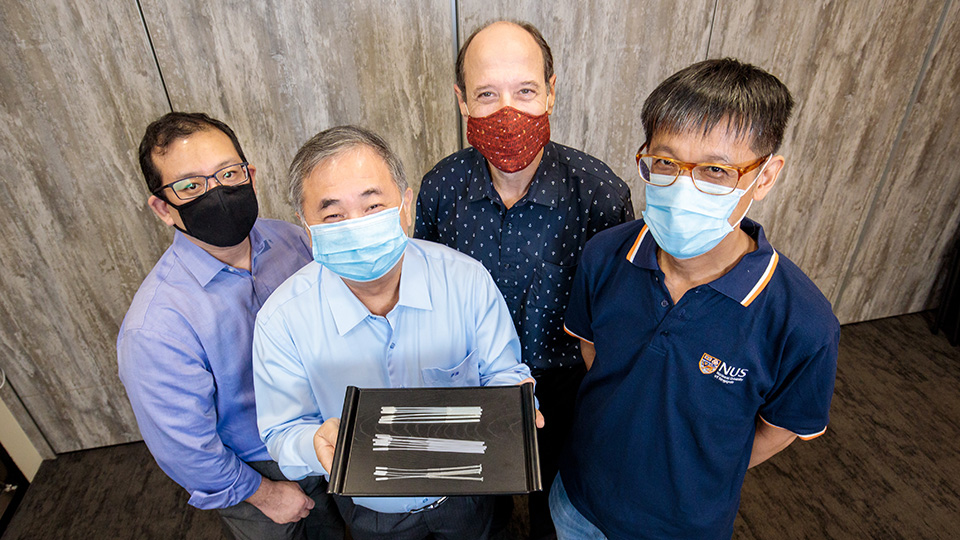

Two teams from NUS have linked up with Temasek Foundation to develop three different swab designs.

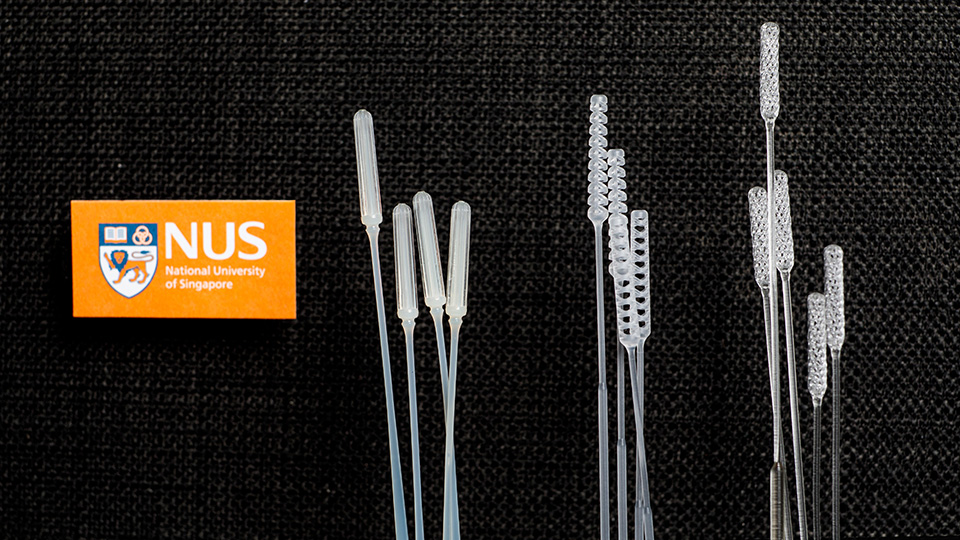

NUS researchers have designed three nasopharyngeal swabs for Covid-19 testing: (from left) IM2, IM3 and Python.

NUS researchers have designed three nasopharyngeal swabs for Covid-19 testing: (from left) IM2, IM3 and Python.

This means that Singapore would have the capability and know-how to produce its own swabs.

Singapore is likely the first country in the world to use injection moulding to produce them, and the first in Asia to use 3D printing for this sort of production.

The 3D-printed swab that has been developed is named Python.

The Python swab uses a double helix structure for the tip.

Trials showed this design has good fluid adsorption and causes minimal discomfort to the patient.

What are nasopharyngeal swabs?

Nasopharyngeal swabs are small, flexible sticks to collect fluid samples from the back of the nasal cavity after it is inserted through the nose.

The tip of the swab has to be specially designed to retain fluid for tests to be accurate.

NUS said Python demonstrated comparable accuracy and performance compared to an industry standard swab when tested on patients with Covid-19.

Mass manufacturing in Singapore: Up to 150,000 swabs a day

The swab's design is free for use in Singapore.

Two local companies is mass producing the swab, and a patent has been filed for it.

Another team in NUS came up with two other swab designs, known as IM2 and IM3, that can be produced through injection moulding.

Injection moulding is a faster process than 3D printing, allowing several hundred swabs to be produced in a matter of minutes.

The two designs made by injection moulding are undergoing clinical trials at NUH and Singapore General Hospital.

Patents have been filed for them as well.

Four companies are likely to mass manufacture and sterilise the injection-moulded swabs.

Each manufacturer can produce 100,000 to 150,000 swabs a day.

This is more than enough for the 40,000 daily tests health officials here are aiming to carry out.

All photos via

If you like what you read, follow us on Facebook, Instagram, Twitter and Telegram to get the latest updates.