Scientists at Nanyang Technological University (NTU) have devised a way to create biodegradable food packaging using a completely organic process and materials.

Organic process with minimal ingredients

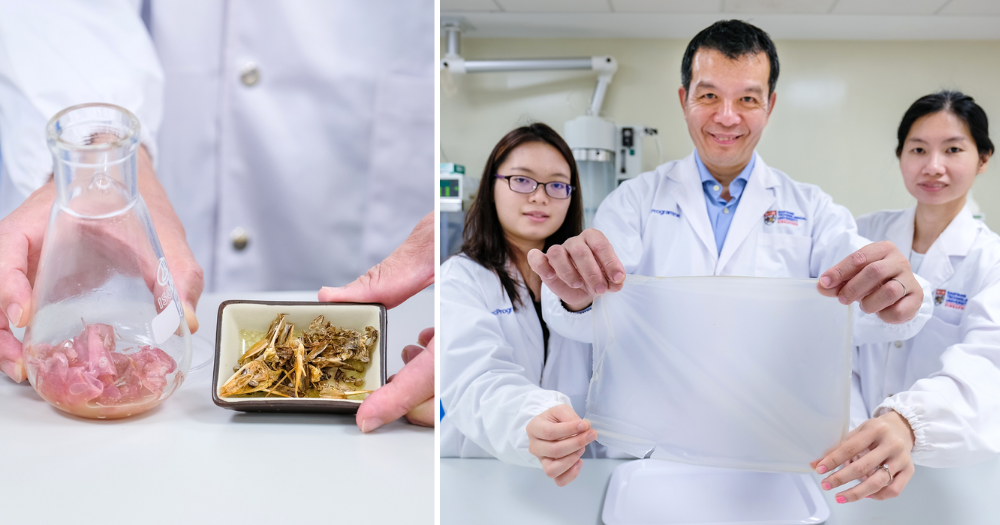

This method involves the combination of two unlikely but common sources of waste—prawn shells and fruit peels.

Professor William Chen, director of NTU's Food Science and Technology programme and his team discovered that sugar in the fruit waste helps kickstart the fermentation process.

Chen and his team tested 10 different types of fruit waste including white and red grape skin, mango peels and apple cores.

They found that grape skin was the most effective in the fermentation process.

This process breaks down the prawn shells into chitin, an organic biopolymer.

Photo courtesy of NTU

Photo courtesy of NTU

Chitin is a compound abundant in nature, and is a component in the shells of crustaceans and insects.

However, it is not commonly used in food packaging as it is not soluble in water, Chen told Mothership. Nevertheless, chitin can be converted into its derivative, chitosan, through further stages of fermentation.

Unlike chitin, chitosan is anti-microbial and more water soluble, and can thus be used to make biodegradable food-grade packaging, replacing the ubiquitous and notoriously unsustainable plastic packaging.

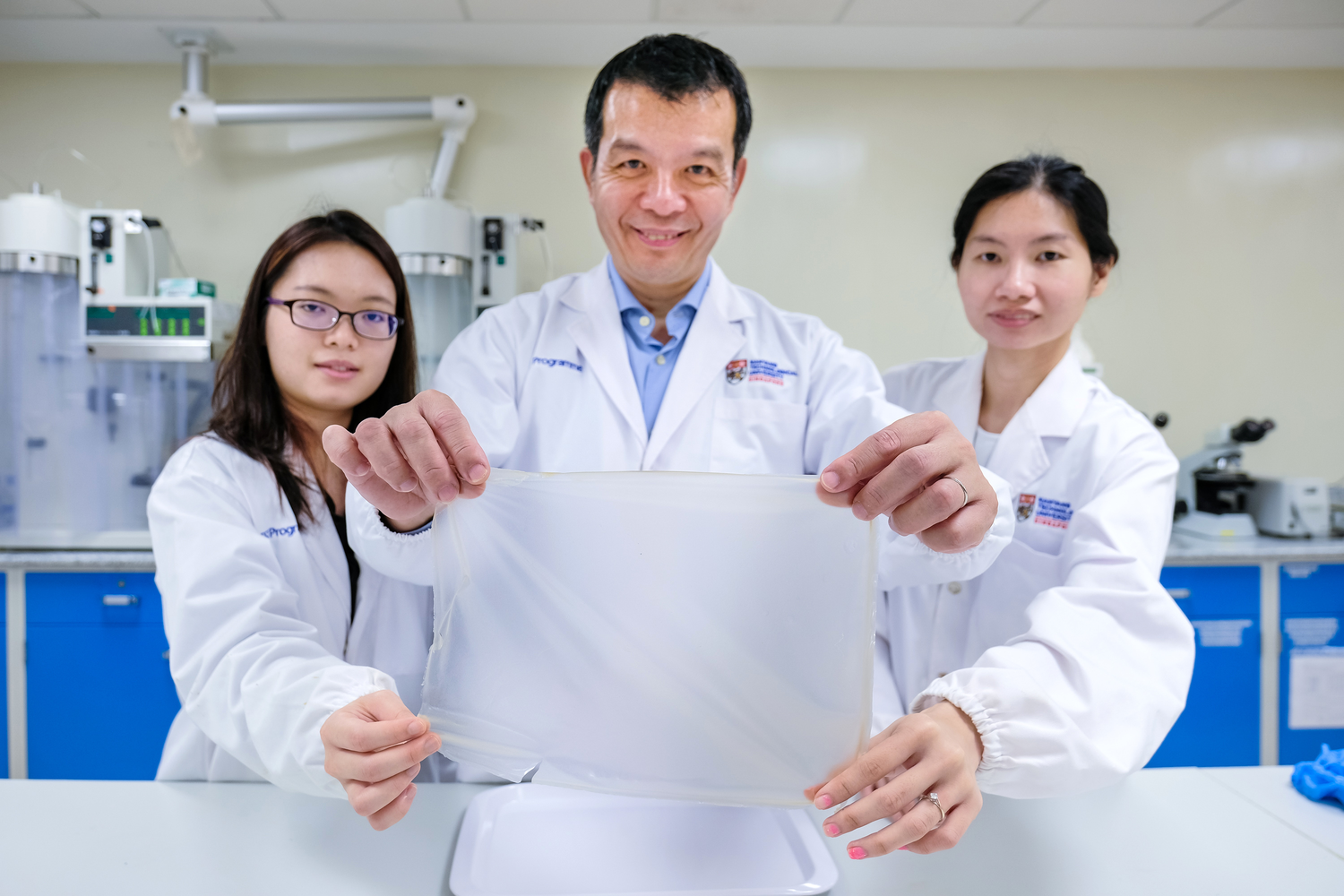

This entire fermentation process takes five days, and the result is a thin, translucent layer of packaging made from prawn shells and fruit peels.

Photo courtesy of NTU

Photo courtesy of NTU

A more sustainable and cost efficient process

Although it is uncertain how much food waste is required to produce one layer of food packaging, Chen's innovative method could potentially be scaled up to industry level and commercialised, which could reduce Singapore's massive production of food waste and green the supply chain as well.

Food waste is one of the biggest food streams in the country, with 744 million kg of food waste generated in 2019.

And despite the increasing awareness of food waste after the Ministry of Environment and Water Resources' campaigning efforts during the Year Towards Zero Waste in 2019, only 18 per cent of this amount was recycled.

Photo courtesy of NTU

Photo courtesy of NTU

Not only could Chen's method help fight food waste, it is a more sustainable approach of extracting chitin from marine waste like prawn shells.

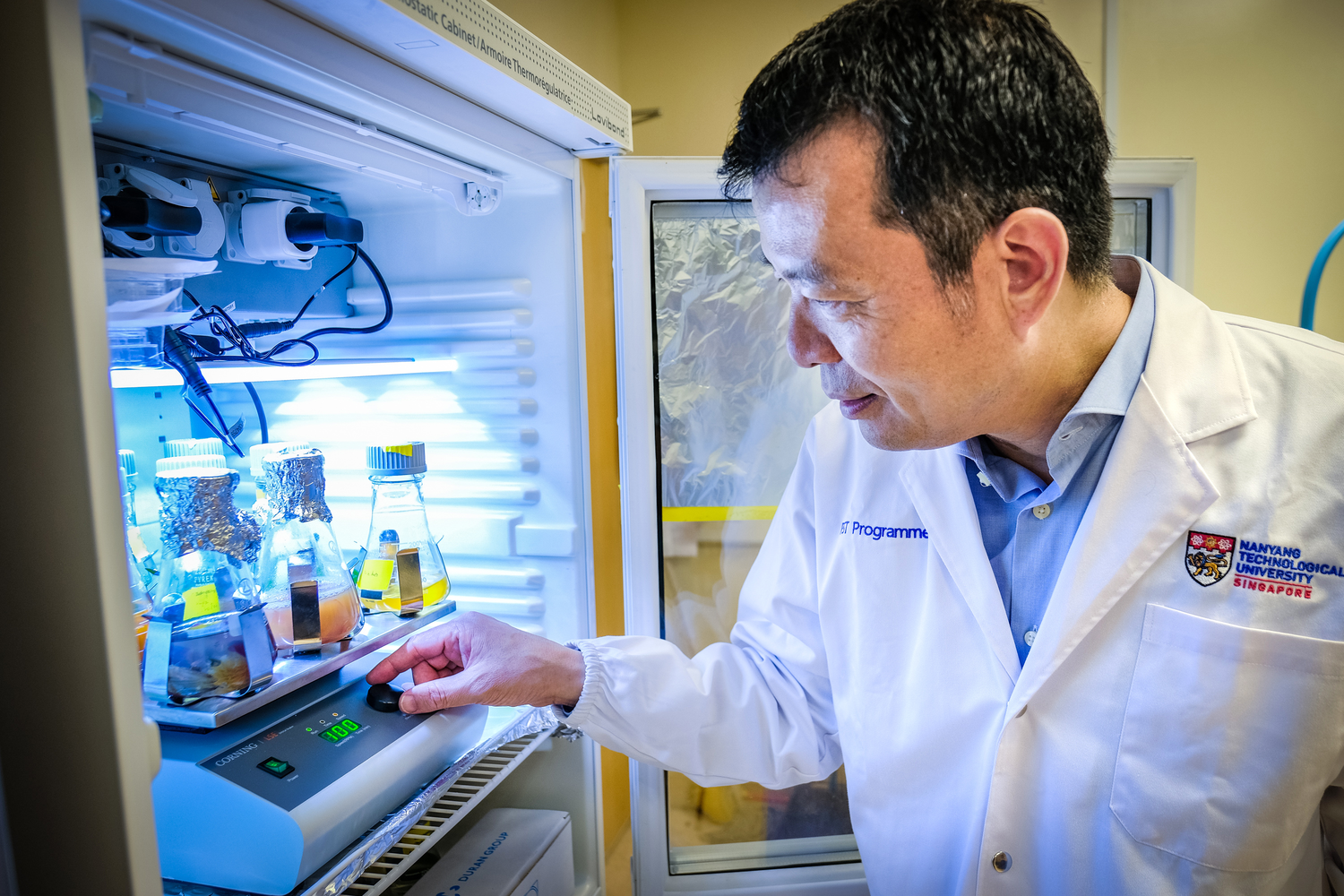

Current approaches that chemically extract chitin—which is also used in food processing as food thickeners and in cosmetics and skincare products—are costly and consume large amounts of energy.

Additionally, the chemical process involves strong acidic and alkaline solutions, to remove the minerals and proteins from prawn shells, Chen said.

This produces environmentally unfriendly by-products like chemical waste.

Chen's method is thus a more sustainable alternative, and as it only requires three things—prawn shells, fruit waste and water—is much more cost effective as well.

Six to eight million tons of crustacean waste are generated annually around the world, with 45 to 60 per cent of shrimp shells discarded as by-products during the extraction process.

And with demand for seafood growing in Singapore and around the world, Chen's method could prove the next big solution for food and marine waste.

Top photo courtesy of NTU

If you like what you read, follow us on Facebook, Instagram, Twitter and Telegram to get the latest updates.