EWL MRT disruption: 800 workers involved in recovery, including some who volunteered, during hot & rainy weather

Challenges included logistical constraints and the weather.

A total of 800 workers were mobilised to help address the disruption of train services on the East-West Line (EWL) between Jurong East and Buona Vista stations which took place

300 of the workers were from the Land Transport Authority (LTA), while the other 500 were from SMRT.

They worked round-the-clock shifts that were roughly 12 hours long.

For LTA, the mobilisation of 300 workers on such short notice is the largest that has occurred to date, said Zailani bin Mohamed Idris, LTA's Deputy Director of Trackwork, in an interview with the media on Oct. 1.

As for SMRT, the activation of 500 workers included all of their track maintenance staff, according to Muhammad Shazni bin Jaffar, a Senior Engineer for Track Renewal from SMRT.

Some of the workers had also volunteered to come down to help out, Shazni said, adding:

"We are very grateful that they sacrificed their weekends and their time (with) their families to (tackle) Singapore's national crisis, to make sure the train resumed service as soon as we could."

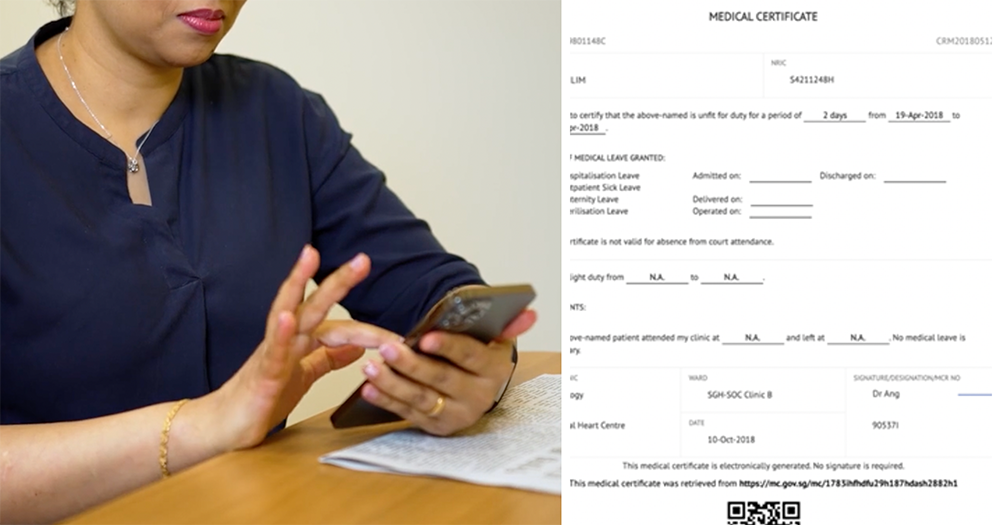

LTA trackwork deputy director: Initial reaction to damage was "Oh my god"

Zailani admitted that when he first saw the damage, his initial reaction was "Oh my god."

"I have not seen any rail break in that manner," he said, and described the damage as "unusual".

The presence of multiple rail breaks meant that the tracks could not be easily replaced.

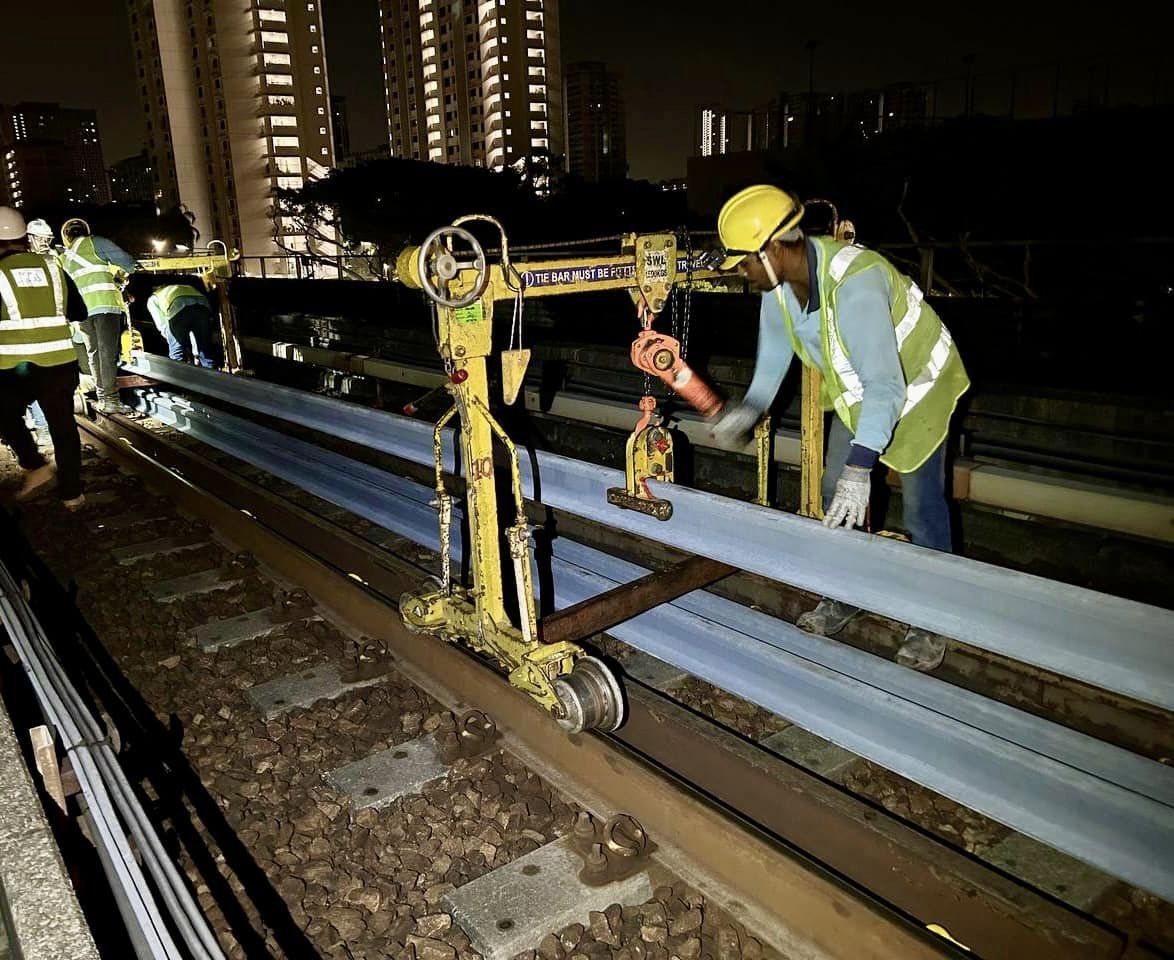

Typically, repair work is done by an engineering train, which travels over the affected point.

For the recent incident, the damaged rails were in a "dead area" with no power.

Workers had to stop before the area affected by the rail breaks, drop the rail from the engineering train, then manually place it on a mechanical jig and push it towards the affected point in a coordinated manner.

One rail is about 18 metres long, weighs about a tonne, and requires about eight workers to push the jig.

The rails had to be delivered to the worksite at night due to logistical constraints.

Zailani said the replacement rails were delivered from two locations: Clementi Depot and Changi Depot.

Source: Photo via LTA/Facebook

Source: Photo via LTA/Facebook

Once delivered, it would take anywhere from 30 to 45 minutes to simply bring a rail over to its intended location, especially since the engineering train had to stop as far as 600 to 700 metres away from the damaged points.

Zailani said 13 rails were delivered in the course of the first night of repair work, which meant that the delivery took several hours.

This was to ensure that the team working the next morning would be able to immediately commence the replacement of the damaged rails.

Other contractors for other MRT lines activated

Other contractors who are involved in ongoing trackwork projects for the Thomson-East Coast Line, the Jurong Regional Line, and the Circle Line were activated by LTA to help replace the affected rails.

These contractors from other ongoing trackwork projects helped to mobilise a large number of skilled and qualified workers to work together.

Their tasks involved carrying out rail cutting, welding of rails, rail grinding with specialised equipment in a short time frame, Zailani said.

According to LTA and SMRT investigations, a train axle box dropped from a Kawasaki Heavy Industries train, causing the wheels of a bogie to come off the running rail as the train was travelling between Dover and Clementi station.

The wheels hit track equipment, including the third rail and point machines, leading to a power fault.

Hot and rainy weather was also a challenge

Another challenge the workers faced was the weather.

Zailani pointed out that works could be carried out in the rain.

As an example, he said if welding is done in the rain, it will likely be of poor quality, thereby making the rail more likely to fail when the subsequent stress test was done.

In addition, if the weather is clear, it is necessary to monitor how hot it is, especially between 10am and 3pm, he said.

If it is too hot, cutting the rails to replace them can be challenging as the rails can get stuck due to the expansion of the rails in the heat.

The SMRT team is also more used to carrying out their track replacement at night, rather than the day, Zailani pointed out, with this incident being the first time they had to work in the day.

"We had to plan accordingly, and rotate the guys, to make sure they don't get tired or pass out from heat exhaustion," he added.

Measures that were taken included placing a tentage over the worksite to protect the workers from both the heat and the rain, as well as keeping a watch for lightning warnings from the National Environment Agency (NEA).

Zailani acknowledged that just walking towards the worksite on the tracks under the heat was already tiring, let alone replacing the rails.

However, morale was generally good among the workers throughout the repairs, he said.

Families were understanding of the situation

Both Zailani and Shazni also said they were thankful for the understanding shown by their families in light of the long shift hours they had to work.

Zailani highlighted that he would usually return home at 3am in the morning.

He said with a laugh that when his daughter, aged 20, realised he was not at home in the day, she simply asked him, "When can (the train service) start?"

Meanwhile, Shazni said his two-year-old son asked him through a video call with his wife to come home to fix his toy tracks.

"That touched me," he said.

"So I'm very grateful that my family understands [what] I'm working on," he said.

Top photos by Mothership and via LTA/Facebook

MORE STORIES